Option 1

PRODUCTION CHARACTERISTIC:

Following the data requirement for the material witch will be processed by the line and the characteristics of the plates at the exit of the line:

A-STRIP CHARACTERISTICS

Composition laminated strip alloy: Al=0,005%±0,002, Sn=0,3-1,2%±0,05 Ca=0,06-0,095% ± 0.005

Strip Thickness: From 0,7mm to 1mm

Strip Width: From 60mm to 90mm

B-PASTE CHARACTERISTICS

Moisture: From 9% to 14%

Density (Cube Weight): From 3,8 to 4,8 g/cm3

Plasticity (Penetration): From 330 to 420 (Humboldt)

Fiber Additives: From 1,5mm

Max Temperature: 45°C

Plate Tolerance

Weight (wet): Nominal +-3g

Thickness: +-0,1mm

Cutting tolerance: at the nodes.

Production Parameters

Line can run up to 32m/min.

Line Composition

The machines are equipped with all necessary safety guard and dust extraction hoods, locking doors and inspection doors, pneumatic system electrical system, and security system in accordance with the European Machinery Directive 2006/42/EC. Are provided Manual of use and maintenance with the EC declaration Language: English

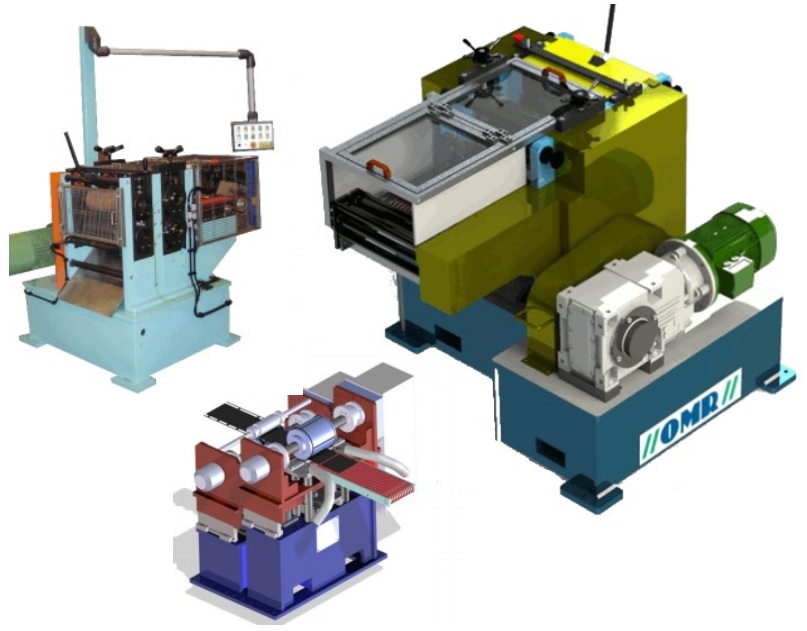

A. Drum pasting machine

This new drum pasting machine has been designed in order to achieve a calibrated thickness of the pasted plate and homogeneous distribution of the active material on the grids. Paper rolls are easy to load with no clamp system and precision is ensured by an adjustment system, this machine permits a perfect adhesion to the pasted grids in order to avoid paper detachments during the subsequent machining. The hopper, with the possibility of side opening, is designed in order to carry out easily inspection and maintenance. The pasting shoes are interchangeable and a daptable to any dimension of length and thickness of the grid desired. The design avoid the jam and drag of the strip inside the hopper. The pasting is carried out by fixed orifice with forced pressure witch guarantee a complete upper and lower covering of the grid obtaining a homogeneous distribution of the active material, in addition allows achieving the desired thickness and planar plates. The feeding of the machine is carried out by an indexed and centered system. This machine have also a set of rollers with the following functions: Checking rollers air pressure ensure the proper pressure desired on the strip.

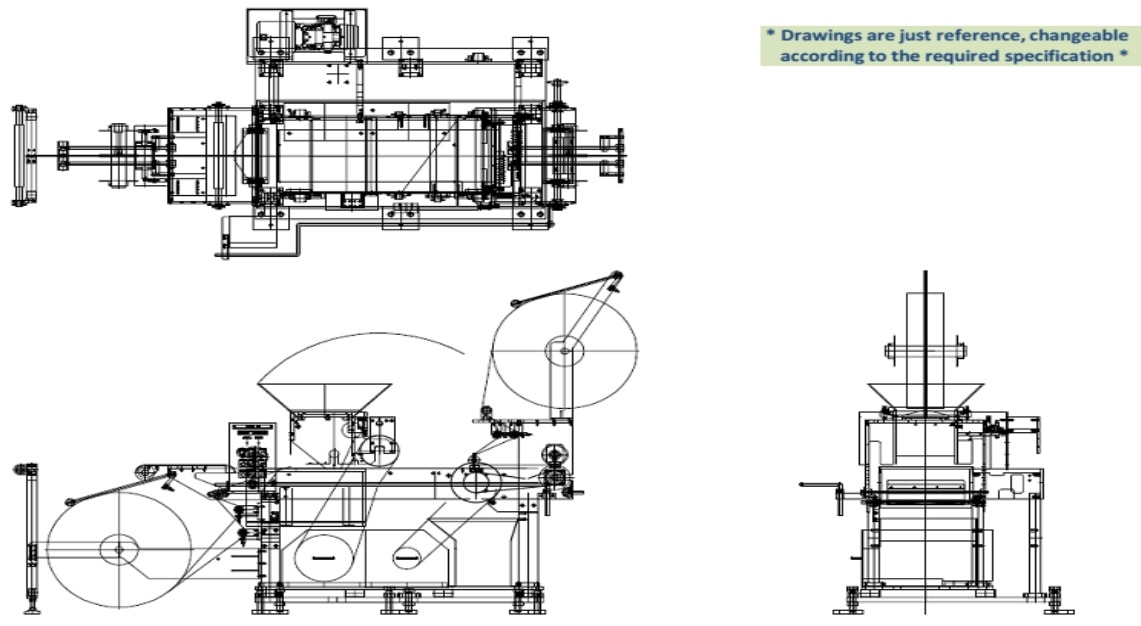

B. Rotary Cutter Machine

The expanded strip is fed into the divider and attached to the suitably formed engagement roller. The cutting is carried out by of steel roller, the upper one of which has slots to contain the interchangeable cutting blades. The lower roller stops the strip moving away as it is cut and is made of tempered and precision ground special steel. After cutting, the plates are extracted by a system which divides them and using lower round belts transports the cuted plates to the output of the divider. The machine consist of:

• N°1 Cutting assemblies including transport belts.

• N°1 Electrical box.

Other characteristics

• Base made of formed welded steel;

• The fittings and quick releases for the precise mounting of the head are also mounted on the base;

• Automatic Grease pump;

Option 2

Machine Information

Pasting machine to Expanded grid

Easy speed control by separated drive between transfer conveyor and pasting hopper

High corrosion resistance by special stainless steel material.

Controls

Mitsubishi Q-Type PLC

Inverter control

Inspection

No special inspection device

Standard features

Pasting paper supplying wheels

Press roller after plate pasting

Divider & Diverging Conveyor

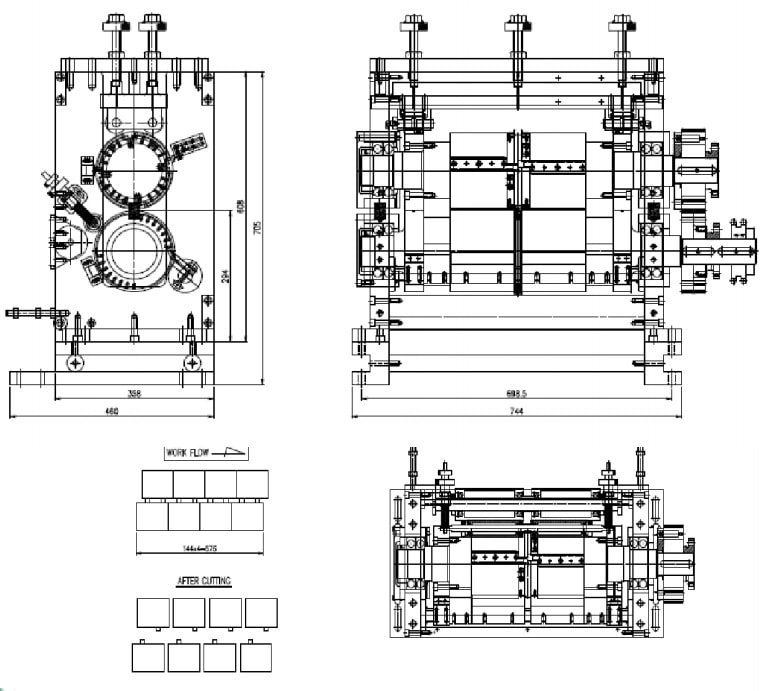

Drawing

Divider (4 Patitions)

Diverging Conveyor

Technical Specification

Divider Ass’y (4 Partitions)

– Frame

– Bottom spindle Ø183.35 x 892L

– Upper spindle Ø183.35 x 806L

– Length knife

– Lug cutter

– Gear Reducer : SEW, 5.5Hp

– Chain & Chain sprocket

Divider Ass’y (6 Partitions)

– Frame

– Bottom spindle Ø206.26 x 940L

– Upper spindle Ø202.26 x 862L

– Length knife

– Lug cutter

– Gear Reducer : SEW, 5.5Hp

– Chain & Chain sprocket

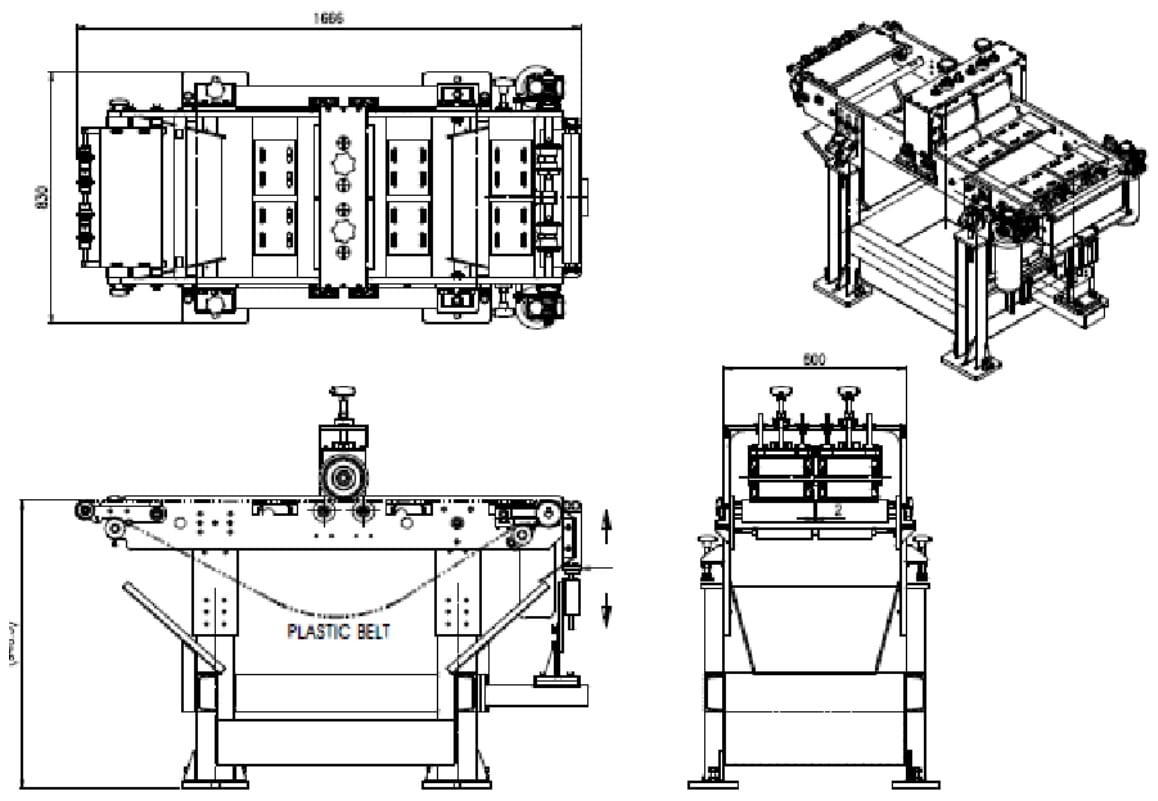

Diverging Conveyor>

– Feed Speed : Max. 50mpm

– Gear Reducer : DSK, 1.0Hp, 2sets

– Plastic Belt

– Tension Unit

– Air Cylinders & Air Unit