Option 1

MODELS:

A.MODEL LS/BML- 1,000G BALL MILLS:

FOR LEAD OXIDE PLANT WHICH EACH CAPACITY IS 1,100 – 1,200 KGS/HR ( 28 TONS PER 24 HR ) With high speed rotary cutting system.

B. MODEL LS/BML- 600G BALL MILLS

FOR LEAD OXIDE PLANT WHICH EACH CAPACITY IS 600 – 650 KGS/HR ( 15 TONS PER 24 HR ) With high speed rotary cutting system.

1. LEAD INGOT CHAIN CONVEYOR.

2. LEAD INGOT APRON FEEDER.

3. INSULATED LEAD MELTING POT (ROUND SHAPE)

4. GAS BURNER MOTOR : 1 Kw

5. MOLTEN LEAD SUPPLY PUMP.

6. LEAD LIQUID FLOW CHANNEL.

7. LEAD BAR COOLING MOULD MACHINE.

8. ROLLER FRAME CONVEYOR as a guide.

9. ROTARY CUTTING MACHINE.

10. CHAIN TYPE APRON CONVEYOR from Cutting

11. LEAD LUMP DISTRIBUTOR.

12. SCREEN MESH CONVEYOR from Lead Lump

13. LEAD LUMP HOPPER with Supporting Frame

14. LOAD CELL for Lead Lump Hopper.

15. Lead Ball TABLE FEEDER to connect the

16. LEAD BALL ROTARY FEEDER.

17. HIGH PRESSURE REACTING BLOWER for Ball Mill

18. AIR HEATER for preheating fresh air.

19. DISCHARGER SILENCER.

20. BALL MILL DRUM mounted with Ring Gear, Pinion,

21. OIL PUMP .

22. SWING SCRAPPER for outlet of Mill .

23. PULSAIRE COLLECTOR (MODEL SP-196-10)

24. HORIZONTAL TABLE DISCHARGER ( WIPER).

25. ROTARY VALVE.

26. SECOND PULSAIRE COLLECTOR (MODEL SP-72-8)

27. ROTARY VALVE of 2nd Pulsaire Collector.

28. REVERSIBLE SCREW CONVEYOR .

29. EXHAUST FAN with Inverter to adjust the speed.

30. DISCHARGER SILENCER.

31. ELECTRICAL VIBRATORS. For the housing of

32. CLEAN PORT DEVICE on Main PULSAIRE

33. JOIN OF PIPING in whole system.

34. ELECTRIC AND CONTROL UNIT FOR LEAD

Including :

A). Mitsubishi Q03 PLC Controller x 1 set

B). All the motor starters for lead ball system.

C). Photoelectric Sensor x 2 sets

D). Weight Indicator x 1 set

E). Temperature Controller x 4 sets

F). 1 HP Inverter input unit x 2 sets

G). 5 HP Inverter input unit x 1 set

H). Other necessary electric parts.

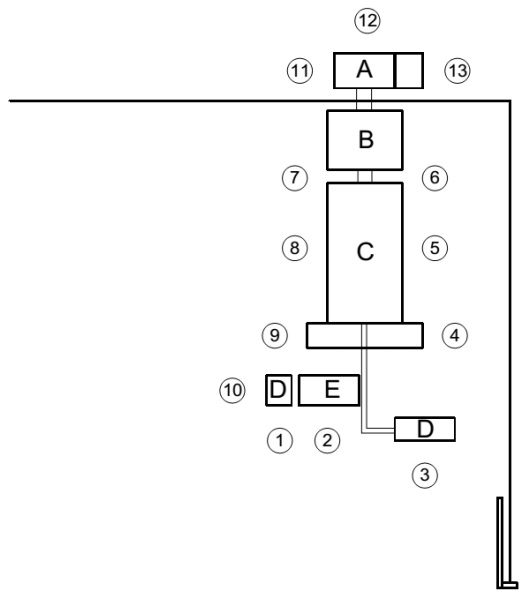

NOISE LEVEL FOR BML-1000 BALL MILL SYSTEM

A: Second Pulsaire Collector with Exhaust Fan

B: Pulsaire Collector

C: Ball Mill

D: Motor

E: Gear Reducer

F: Reacting Blower

Between each checking position to the machines is 1 meter.