Option 1

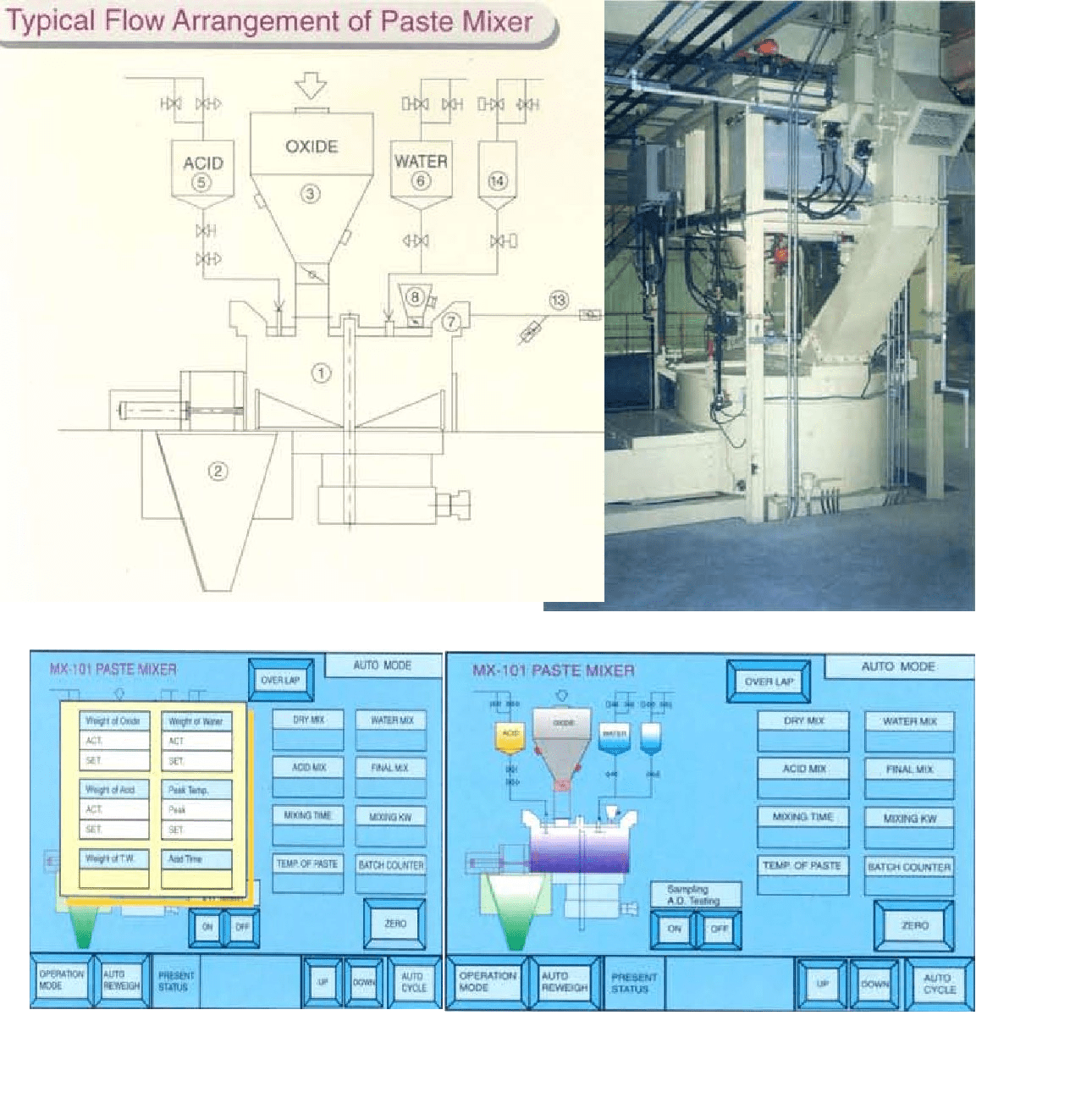

PASTE MIXER SYSTEM

C1. PASTE MIXER MODEL NO. : MX-101.

MAX. CAPACITY : 1,000 Kgs

Side Wall of Mixer equipped with COOLING WATER JACKET.

C2. ROTARY CONE PASTE DISCHARGER

CAPACITY : 1.2 tons

C3. SLIDING DOOR DEVICE for PASTE CONE FEEDER

C4. OXIDE WEIGHING TANK

MAX. CAPACITY : 1,500 Kgs.

With two AIR VIBRATORS to relieve the oxide residue.

C5. DISCHARGING BUTTERFLY VALVE Control

By Air Actuator Including Solenoid Valve.

C6. ACID BUFFER TANK With SUPPORTING FRAME.

C7. WATER BUFFER TANK With Supporting Frame.

C8. EXHAUST AIR DAMPER.

IC9. ADDITIVES FEEDER with Butterfly Valve

C10. A. D. DISCHARGING PORT for testing the paste.

C11. TRIMMING WATER TANK.

C12. COOLING AIR CONDITIONER.

C13. SYSTEM PIPING.

C14. MAINTENANCE STAGE

C15. ELECTRIC CONTROL UNIT

system performance

HGJ-1000 automatic paste system is suitable for batteries production and paste section. The system integrates the functions of lead powder

conveying, lead powder automatic weighing and feeding, water and acid automatic weighing and adding, automatic mixing, automatic

water replenishing, etc. It has auxiliary functions such as host load display, motor stop-up alarm, paste over-temperature alarm, acid

mist automatic discharging, etc. The whole system is composed of PLC and man-machine dialogue interface produced by TOUCHWIN

COMPANY, Canada. The whole production process is centralized and automated. Automatic completion of lead powder feeding, weighing,

acid, water weighing, adding powder and water adding acid, fast and paste, lead paste storage and other functions. The system is designed with distributed structure, which is highly integrated, safe, reliable and durable. It has the function of self-diagnosis, which can find out the

fault location conveniently and quickly, and restore the system function in time.

System Composition and Technical Parameters

TAHG-1000 paste system are composed of the following equipment,

the main technical parameters of each equipment are as follows:

1. Quick Paste Machine

a-Maximum weight of lead powder for one time paste 1000KG.

b-Maximum lead paste production per hour 1200KG.

c-Rated power of motor 45KW.

d-Compressed air consumption 0.6MPa 0.015m3.

e-Air volume of exhaust fan 3000m3/h.

f-Cooling water quantity 2T/h

System Composition and Technical Parameters

TAHG-1000 paste system are composed of the following equipment,

the main technical parameters of each equipment are as follows:

2. Lead paste storage bucket:

a- Effective volume 350L .

b- Storage of paste 1.5T.

c- Rotational speed of paste hopper 8 speed/min.

d- Rated power of traction motor 4KW.

3.Lead powder weighing bucket:

| a- Maximum weight at a time b- Quantify precision | 1000KG ≤0.5% |

| c- Repeated Measurement Accuracy | ±0.5KG |

| d- Vibrator power 4. Lead powder storage bucket a- Lead powder reserves b- Feeding capacity | 250W |

| 1000KG ≥25KG/min |

(Note: Depending on the system, the register bucket may not match.)

5. Acid and water weighing box

| a- Effective volume b- Measurement Scope | 180L |

| 10-160L | |

| C- Repeated Measurement Accuracy | ±0.5% |

| 6 Electrical control cabinet | |

| a- TOUCH WIN Industrial touch screen |

True color LCD, service life over 50000h

Resolution 480*600

b- THINGET XC3-48 PLC Main module, XC3-8AD Analog module

The system sensor uses 4-20 mA teletransmission analog signal C- 0.2 level weighing sensor and temperature, current transducer.

The system accuracy is guaranteed.