1.Application

The machine used to produce the negative grid of industrial battery

2 .Composition and Function:

2.1 Composition:

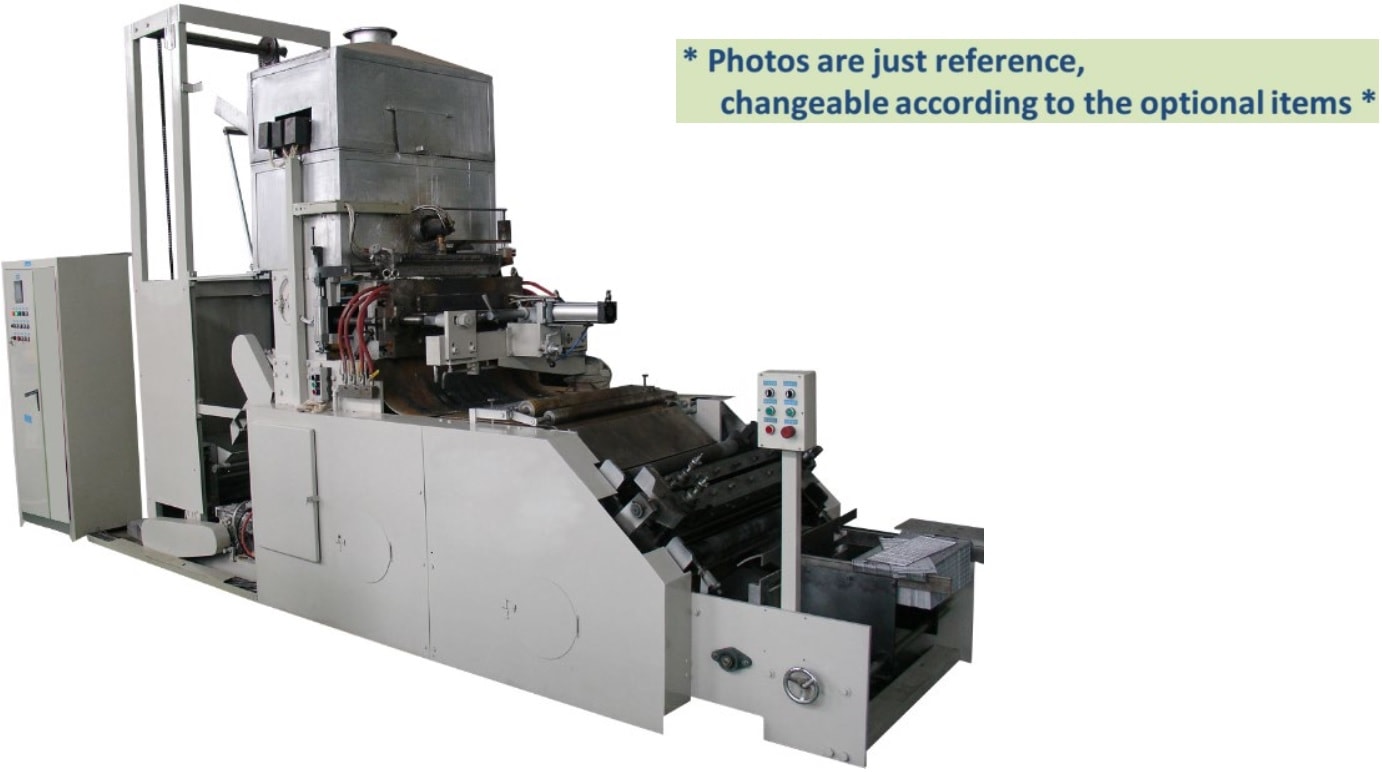

Casting Machine, Lead Spoon, Mould, Trimming Blade, Grid Collection Rack,Lead Pot(3Ton), Lead Pipe

2.2 Performance Feature

♦The main machine uses the mechanism transmission design, while the lead ingot feeding, casting,mould-opening, mould-closing, grid-turn over controlled by pneumatic device.

♦The thermocouple fixed on mould to control the mould heater and temperature. The mould heating temp and working temp are independent display. So when the heater off, turn on the main switch to show the mould temp. Cooling water to keep the mould running temperature.

♦ The transmission design of main machine: The mould open-close and lead liquid supplying is controlled by reliable pneumatic unit, while other parts adopt mechanical transmission. The stepless speed control for main machine with wide working range and easy operation.

♦We choose the big dia and light material Pressing Roller in grid transportation, effectively solve the grid bending and deforming in transportation (especially the thin and soft grid)

2.2 Performance Feature

♦ The grid moves into the trimming blade with even speed, in case grid deform in high speed and increase the rejection.

♦ The trimming blade is designed with long size, bottom fixture for multiple size grid production.

♦ Lead supplying system Control the lead volume by Magnetic ball and valve core made of special material with reasonable expansion coefficient, precision fit and volume control, less lead stuck , leakage and easy maintenance.

♦ PLC controls the whole system with reliable performance.

3.Specification

Production Capacity: 4~8pcs/ min

Max Grid Size: W700 mm× H(130~250) mm× Thickness(2.5~6)mm

Machine Overall Size (Including Lead Pot): 长 L3700mm× W3800 mm× 高 H2450mm

Gross Weight: 6000 Kg

Lead Pot (3T)Temp Control: 430℃-550℃

Mould Temp Control: Up Mould: 150℃ -170℃

Fixing Mould: 170℃-190℃

Lead Pipe Temp Control: 450℃–520℃

Lead Spoon Temp Control: 450℃-550℃