-Equipment Parameter

1. Application:

。 Used for production of tubular positive plate with Pb-Sb or Pb-Ca alloy.

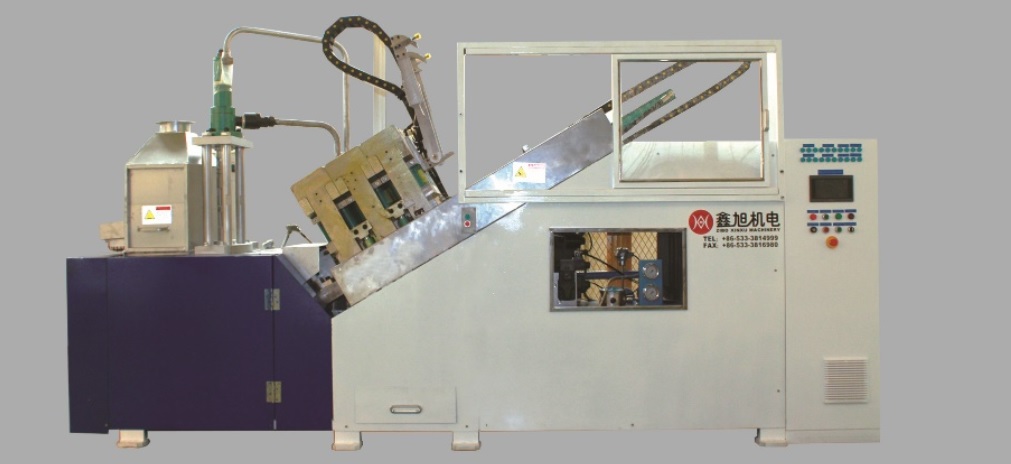

2. Composition:

。 Main Machine,Normal Cutting Machine and Mould

2. Cycle Time:

。 Die Casting Machine: 3 cycles/min.

3. Parameter:

。 Spine Length: 280mm—630mm

。 Spine Width: ≤220mm

。 Spine Dia: ≥3.0mm, compatible with spine height(Pls show spine drawing for approval)

6. Machine Painting:

。 PDC Main Machine: White

。 Safety Guard: RAL2009 (Orange)

– PDC Operation

a. Power Supplying:

Power Supply: 380V ± 10%; 50Hz; 3 phase 4 lines

Control Voltage: 24V DC(24V)

Power Consumption: 52KW (PDC)

b. Compressed Air:

Pressure: 5.0-6.0bar

Consumption: 1.4M3/hr

c. Cooling Water

Temp: 20℃-25℃ ,Flow: 5M3/hr, Pressure: 0.2-0.3Mpa

d. Hydraulic System:

Hydraulic Oil: N46 Wear-resistant hydraulic oil

Oil Temp: <55℃

Working Pressure: ≤28MPA

Lead Pump Volume: 432ccm

Injection Pressure: 80-130bar (110bar)

Clamping Pressure: ≤28MPA

Cleanliness: NAS7

-Equipment Parameter

Component Brand List

1. Electrical Parts

PLC: Siemens S7-1200 ,HMI : Kinco MT4403T

Frequency Driver: Siemens

Air Beaker: ABB

Relay: Omron

Motor: Wolon

Limitation Switch : Omron

2. Pneumatic Parts

Valve: SMC

Cylinder: SMC

Pipe and Connector: SMC

3. Hydraulic System

Proportional Valve: Atos

Solenoid Directional Valve: Yuken

Hydraulic System: Yuken

Hydraulic Valve:Yuken

Gauge :Yuken

CylinderL:Faster

-Spine Quality Standard:

1. No Burrs

2. 2mm,5% Flash dia not more than 2mm,within 5% of total surface area.

3. <2mm No porous hole at surface,but <2mm area allowed internally at frame only

4. No spine cracks

5. Weight tolerance: ±0.5%

6. Spine Dimension: As customer Signed drawing.