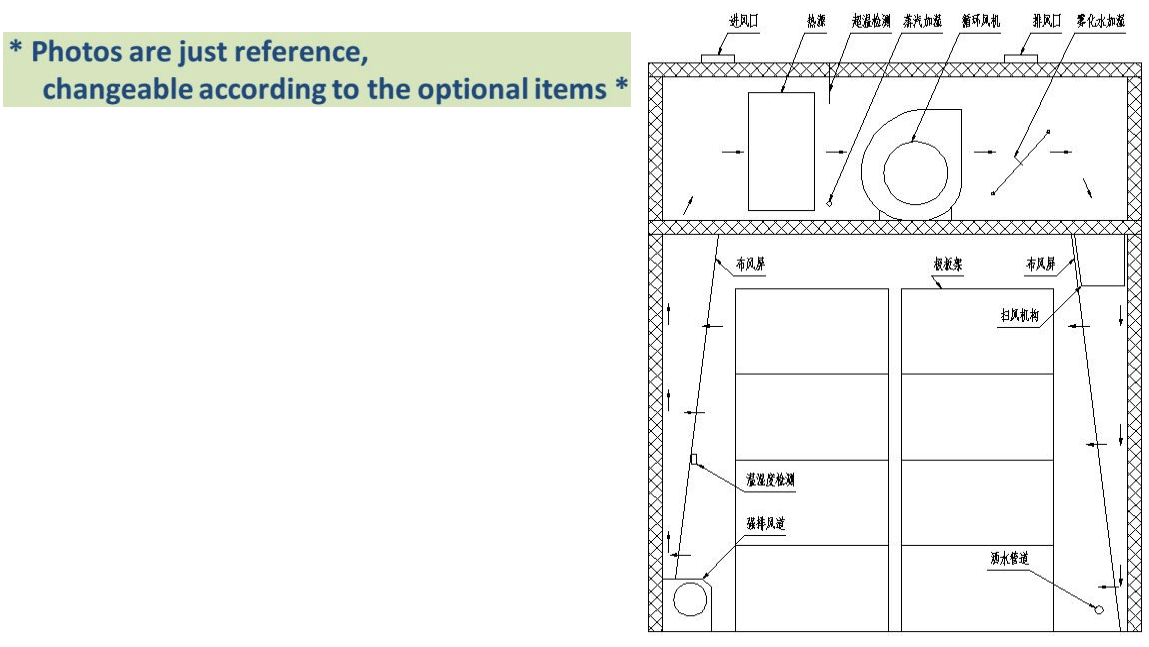

The curing and drying chamber is an advanced product which absorbed American OSI technology. As an ideal substitute of imported products,

it could automatically fulfill the curing and drying procedure automatically without guarding.

40Q(Electrical heating)

General Instruction

1. Control range:

Curing Period:

temperature: 0~65℃ ; humidity: above 95% (with steam humidification)

Drying Period:

Temperature: 0~85℃ ;humidity: below: 15%

2 .Control accuracy:

Temperature: Setting value±2℃

3. Inner size: 40m³

4. Circulating fan: Motor power:7.5KW(the air amount is subjected to the size of the room and changes through inverter)

5. TMP. & Humidity checking:: Adopting the wet and dry bulb sensor

6. Compressed air pressure : 0.4MPa~0.6MPa

7. Water pressure: 0.2MPa~0.3MPa

8. Power: 3 phase, 380V/220V, 9KW

9. Noise standard: ≤75dBA

10. Heating way: Electrical heating

11. Standard configuration has no steam humidification line and the corresponding control system; If customer apply large boiler, the steam pressure should be 0.3~0.6Mpa;

Main Features

1. Curing & Drying process can be completed in one time and also independently.

2. Imported temperature & humidity transducer with high temperature resistant, anti acid mist and dust, long service life.

3. PLC control, touch screen operation panel (both Chinese/English Language), 10 sets of different process parameters can be stored in advance. Each set includes max 20phases, with max 999 mins/each phase.

4. Humidification has two ways, atomized water and steam. It can switch automatically according to the actual temperature and customer’s demand.

5. Adopts three-dimensional wind way and stainless steel circulation fan, the temperature & humidity in the room keep even. Then physical and chemical index keeps consistency after curing and drying.

6. Full set of Sound, Light and Text Alarm to remind the Fan circuit problem, Temp over limit and Air/Water pressure alarm.

7. Touchable monitor can display the running status of fan, spray, etc. Inner side of Chamber is made of SS steel, Outside is made of Color Steel, Polyurethane is filled in between with good thermal insulation performance.