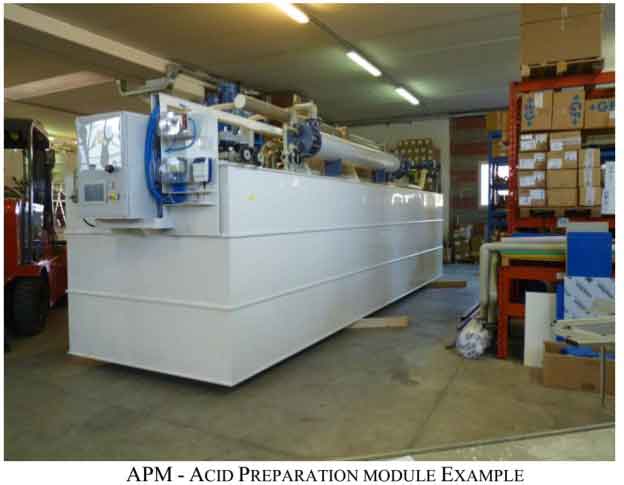

▣ Description :

▶ The module is automatic and managed by an on-board panel.

▶ The module is suitable for indoor installation and not for outdoor installation.

▶ The system can provide and store one acid density at a time.

▶ This unit is composed by one insulated double wall tank in PP/PPS, for the automatic

▶ preparation of the requested acid gravity at 30-35°C.

▣ REQUIRED INPUT :

▶ The input required are:

– Demi H2O

– Raw Acid 1.8

– 2-shot acid to be recovered

– H2O chilled (water circuit 7-12°C)

– Compressed Air (min 6 BAR)

– Data network – VPN connection

– Electrical Power

– Exhaust air connection

▣ TECHNICAL CHARACTERISTICS :

▶ The system prepares the acids requested automatically in order to assure the availability of the requested acid.

▶ The APM performance can vary in case of different acid densities to prepare.

▶ The module includes:

• Sedimentation tank for acid filtering;

• Pumps for mixing and sending of acid,

• Valve for Raw acid,

• Valve for H2O demi,

• Valves for internal acid circulation;

• Valves for ready acid,

• Ultrasonic levels and emergency levels,

• Temperature sensors,

• Refractometer for fine density reading,

• Internal cooling coil (cooling water temperature request 7-12°C)

• Heat exchangers in graphite (cooling water temperature request 7-12°C)

• Valves and connections for cooling water from/to external chiller (chiller not included in OMI scope of supply)

• Electrical and Pneumatic control panel with touch-screen HMI.

▣ General Dimensions:

• L7700 x W2000 x H2500+300 mm circa

▣ Pneumatic:

• Operating Pressure Dry Air: 6 bar nominal

▣ Electrical:

• Components: Siemens

• Station Logic: Siemens

Safety guards compliant with European Health and Safety regulations.

▣ OPERATION :

The module prepares acid with desired density.

Starting from the parameters set in the management system, the system calculates the volume of raw acid, demi water and recovered acid needed to reach the desired density. The preparation is a continuous process.

The density is checked continuously by a refractometer.

The temperature during dilution is controlled by a heat exchanger and cooling coils Internal to the tank.

At request, the acid is sent to the user by pneumatic pump.